WHAT IS STANDARD EN/IEC 60068-2-75?

HAMMER TEST

Standard EN/IEC 60068 consists of 3 methods for testing the impact resistance of a test object against impacts with different severity levels. It serves to demonstrate the mechanical strength of a product and is intended primarily for the testing of electrical equipment. The test consists of a standardised test procedure with a defined number of impacts on the test object with a defined impact energy. Standard IEC 60068-2-75 covers impact energies from 0.14 J to 50 J.

EN 60068-2-75 DIMENSIONS TABLE OF IMPACT ELEMENTS

IK CODE | IK00 | IK01 | IK02 | IK03 | IK04 | IK05 | IK06 | IK07 | IK08 | IK09 | IK10 | IK11 |

Impact energy (Joule) | * | 0.14 | 0.20 | 0.35 | 0.50 | 0.70 | 1.00 | 2.00 | 5.00 | 10.00 | 20.00 | 50.00 |

Drop Heigth (mm) | * | 56 | 80 | 140 | 200 | 280 | 400 | 400 | 300 | 200 | 400 | 500 |

Mass (kg) | * | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.50 | 1.70 | 5.00 | 5.00 | 10.00 |

Material | * | P1 | P1 | P1 | P1 | P1 | P1 | S2 | S2 | S2 | S2 | S2 |

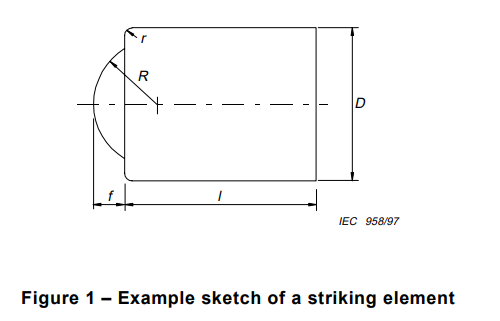

R (mm) | * | 10 | 10 | 10 | 10 | 10 | 10 | 25 | 25 | 50 | 50 | 50 |

D (mm) | * | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 35 | 60 | 80 | 100 | 125 |

f (mm) | * | 6.2 | 6.2 | 6.2 | 6.2 | 6.2 | 6.2 | 7 | 10 | 20 | 20 | 25 |

r (mm) | * | – | – | – | – | – | – | – | 6 | – | 10 | 17 |

l (mm) | * | Must be adapted to the appropriate mass | ||||||||||

Swing hammer | * | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

Spring hammer | * | Yes | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No |

Free fall hammer | * | No | No | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

Specifications from the standard EN 60068-2-75

* not protected according to the standard

1.Polyamide 85 ≤ HRR ≤100 Rockwell hardness according to ISO 2039/2

2.Steel Fe 490-2 according to ISO 1052, Rockwell hardness HRE 80...85 according to ISO 6508

Table 1 Striking element characteristics

Energy / J | ≤1 ±10% | 2 ±5% | 5 ±5% | 10 ±5% | 20 ±5% | 50 ±5% |

Equivalent Mass ±2%kg | 0.25(0.2) | 0.5 | 1.7 | 5 | 5 | 10 |

Material | Nylon | Steel | ||||

R/mm | 10 | 25 | 25 | 50 | 50 | 50 |

D/mm | 18.5(20) | 35 | 60 | 80 | 100 | 125 |

f/mm | 6.2(10) | 7 | 10 | 20 | 20 | 25 |

r/mm | - | - | 6 | - | 10 | 17 |

l/mm | Adjusted according to the equivalent mass, see Appendix A | |||||

Table 2 Height of Fall

Energy /J | 0.14 | 0.2 | (0.3) | 0.35 | (0.4) | 0.5 | 0.7 | 1 | 2 | 5 | 10 | 20 | 50 | ||

Equivalent Mass /kg | 0.25 | (0.2) | 0.25 | (0.2) | 0.25 | (0.2) | (0.2) | 0.25 | 0.25 | 0.25 | 0.5 | 1.7 | 5 | 5 | 10 |