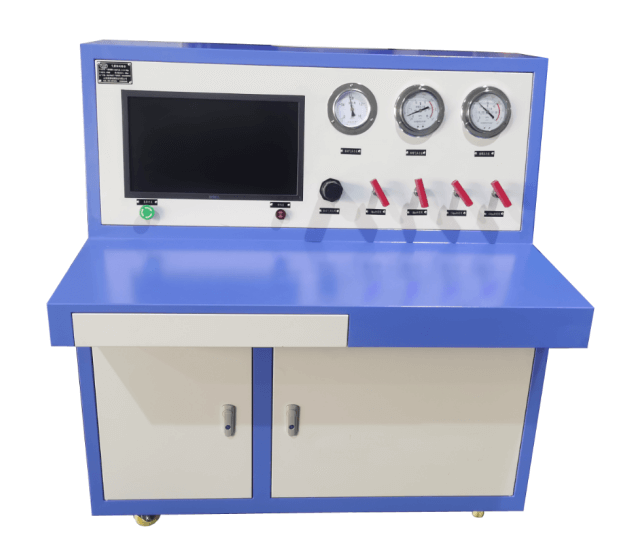

Product Description:

Name:IEC 60335 64Mpa Fully automatic Hydraulic Pressure Test Equipment

Type:BND-HPT-64

Product Overview:

This hydraulic pressure test apparatus is required by IEC 60335-2-5 cl.22.101,IEC 60335-2-7 cl.22.101 , IEC 60335-2-21/35 22.47 & 22.103 , IEC 60335-2-24 cl.22.7, etc.

Hydraulic pressure test range | 0.2-64Mpa (steplessly adjustable) | Test medium | Clean liquid water |

Test station | 1 station | Medium temperature | Normal temperature |

Power device | Gas-liquid booster pump | Outlet flow | 1.2L/min |

Water injection pump | Stainless steel self-priming pump | Electromagnetic valve | Sanlixin |

Clean water tank | Stainless steel | Electro-controlled proportional valve | SMC |

Control method | Computer control | High pressure gauge | KEMAI |

Computer | Dell computer | Box shape | Q235 spray treatment |

Products & Services

Hydraulic Pressure Testing Equipment

Our hydraulic pressure testing equipment is designed for a wide range of applications including hydraulic hoses, hose assemblies, automobile brake pipes, pressure vessels, and powertrain pipes. Our systems ensure accurate and reliable pressure performance tests.

Key Features:

*Pressure Range: 0.2-64Mpa (steplessly adjustable)

*Test Medium: Clean liquid water

*Test Station: 1 station

*Medium Temperature: Normal temperature

*Power Device: Gas-liquid booster pump

*Outlet Flow: 1.2L/min

*Water Injection Pump: Stainless steel self-priming pump

*Electromagnetic Valve: Sanlixin

*Clean Water Tank: Stainless steel

*Electro-controlled Proportional Valve: SMC

*Control Method: Computer control using Dell computers

Additional Features:

Non-welding connection pipeline system.

Separation of test fluid system and drive fluid system for better temperature control.

Customizable software written in force control configuration software or LABVIEW.

Automatic pressure compensation during tests.

Protective tools for operator and equipment safety.

Real-time data display and automatic test report generation.

System Technical Parameters:

Gas Source Requirements:

Pressure: 0.2-0.8MPa

Flow Rate: 1.0Nm3/min (provided by customers)

Performance Metrics:

High Pressure: 0.2-64Mpa

Pressure Increase Rate: Proportional control (0.1-1MPa/S)

Measurement Accuracy: ±0.5%FS

Pressure Holding Time: Adjustable in seconds

Data Acquisition & Control:

American NI high-speed acquisition card (100,000 times/S)

Labview software for peak record measurement and control

Other Specifications:

Working Temperature: 0℃ - 80℃

Output Interface: RC1/4 internal thread

Control Box Size: 1200*700*1300mm